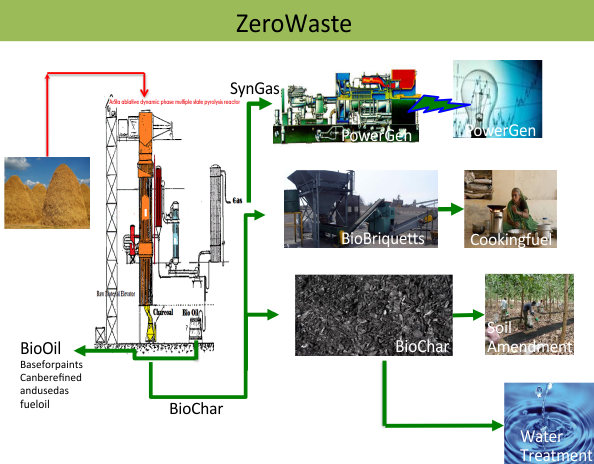

Producing any high end product demands high end technology. At Arsta eco we have developed state of the art equipment that allows us to harvest multiple products from one feedstock leaving ZERO waste. Our Pyrolysis reactor® is a continuous feed 2 stage vessel capable of running 24/7 and accepting multiple feedstocks. Various add on processing components make up the production architecture. Pyrolysis is the thermo chemical combustion of organic material in the absence of oxygen.

At Arsta eco one of the crucial elements of being able to prescribe high quality products is the ability to tightly control temperature, residence time and throughput velocity.

All organic materials are formed in some part, in fact in most part , from carbon molecules and these carbon molecules are crucial to the production of a high quality BBQ brikett. When pyrolysed volatiles are forced out of the structure and are dealt with by the process. This leaves a very high carbon content charcoal to be used to make the brikett. But where our technology differs greatly from many highly polluting methods is the use to which we put the harvested materials that will not form part of the brikett. The gasses , such as methane, Hydrogen and Carbon Monoxide are captured , cleansed and converted into renewable energy. In traditional pit, kiln and beehive methods deployed by the vast majority of charcoal producers these gasses are released to the atmosphere.

These are part of the family of gasses known as GHGs ( GreenHouse Gasses) and are scientifically proven to be responsible for disrupting our atmosphere and the weather patterns the atmosphere controls. In fact Methane is 21 times more dangerous than Co2 so releasing this neat into the atmosphere is very problematic.

It is of course partly true when traditional producers claim their product is C02 neutral . After all very few producers are transparent about their methodology. The true part of the argument is the wood when it was growing consumed Co2 and when it is combusted as charcoal on a BBQ converts the Carbon Monoxide to C02 and so this delivers the neutrality. But unless something has been done to capture the Methane and other gasses this claim is at best a half truth.

In addition, despite what appears as a dry material , all organic materials when pyrolysed will give up moisture in the gasses. These condensates if allowed to enter the atmosphere or leech untreated into groundwater systems will cause everlasting damage. At Arsta eco we capture these liquids and are currently working with a number of universities who are field trialling various fossil fuel displacing uses of the liquids. Once the research is complete we will share this information and invite collaborations with various bodies.

The end result is a very high fixed carbon, low volatile charcoal. Even the way it sounds as it exits the reactor is a sign of quality.